High-speed Inspection Technology

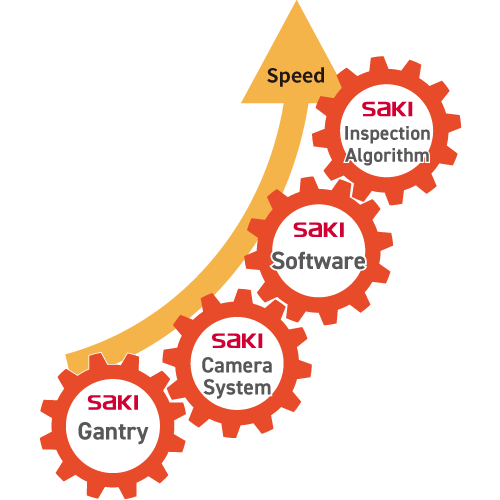

Pursuing higher speeds requires a wide range of technologies ranging from the hardware design to development of the image processing software. Optimizing parts, such as cameras, processing imaged data, and coordinating the each component’s operation are all essential.

Saki’s products and key technologies are all developed in house, allowing the comprehensive optimization of all processes and hardware involved in imaging.

Advantages of in-house development: High speed

If everything is developed in-house

If the key technology is not optimized

01

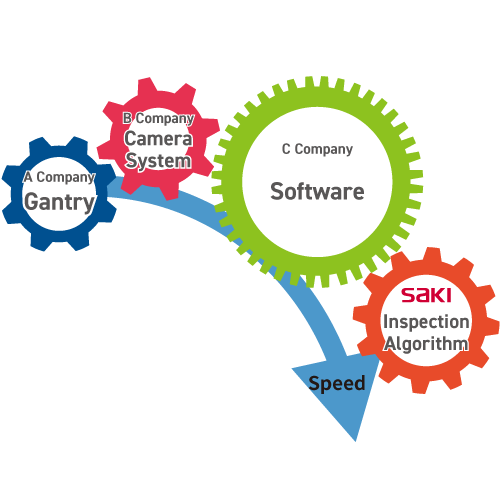

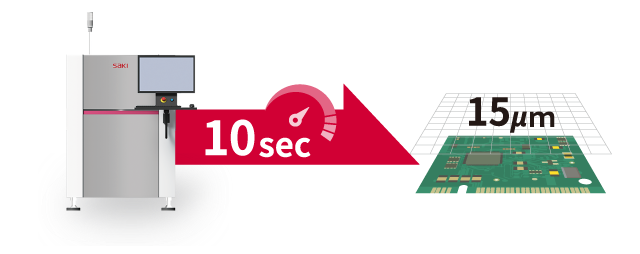

Wide-area imaging to shorten cycle time

Saki’s latest AOI and AXI benefit from an expanded field of view size, allowing imaging with a smaller FOV. The AOI has an optimized optical system to accommodate the expanded field of view, achieving industry firsts of 4500mm²/sec with the 8µm camera, and 7000mm²/sec using the 15µm camera.

With combined optimization of both the wide-area imaging detector and image processing technology, AXI machines have reduced takt time by 50% when compared the previous model.

board in A5 size (150mm x 214mm).

* The inspection time may vary depending on the inspection

condition.

02

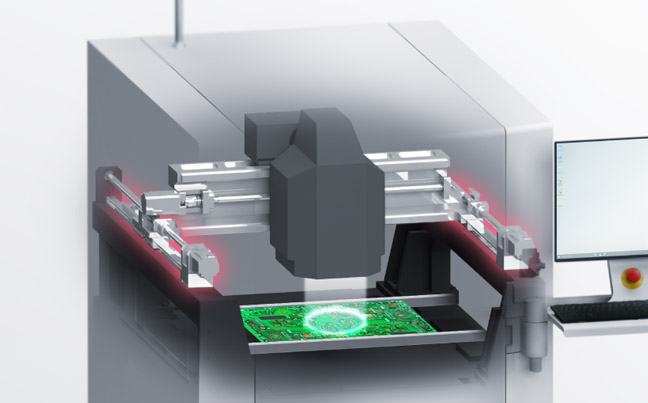

Hardware structure that enables high-speed movement of the optical head

Saki’s AOI, AXI, and SPI solutions have been upgraded to incorporate an highly-stable biaxial structure for the driving part gantry. This combined with the ultra-rigid frame and fully closed-loop motor drive ensures exceptional stopping position accuracy. This hardware structure allows high-definition images to be captured even when the optical head moves at high speeds.

AOI/SPI gantry structure

03

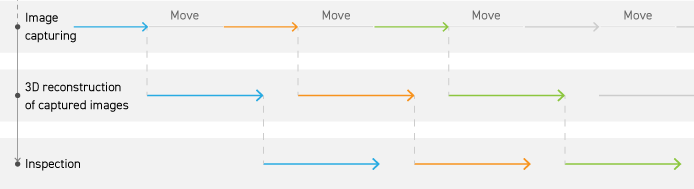

Advanced image processing to reduce unnecessary waiting time

Saki develops custom software for a consistent image processing process, from imaging and data processing through to 3D image rendering.

Image processing is performed concurrently alongside imaging, reducing unnecessary waiting time during process transitions and speeding up cycle times. Both AOI and SPI use the same software, developed in-house to fully optimize the process, while AXI rendering of 3D images and CT calculations for X-rays similarly benefits from bespoke software developed in-house for full hardware integration.

Optimization image from imaging to inspection

Simultaneous processing

Both exceptional speed and unparalleled accuracy are possible!

Across the industry, there is a belief that there must be a trade-off between inspection accuracy and faster cycle time. Saki has attained significant improvements in speed while maintaining inspection accuracy thought constant refinement, including achieving uniform brightness within the field of view through calibration, and improving the striped pattern for height measurement using an in-house projector.

Saki will continue to provide high-precision, high-speed inspection equipment to contribute to continued quality assurance at our customers’ production sites.