X-ray Inspection Technology

The demand for X-ray inspection is increasing for quality assurance of high-density printed circuit boards and power modules for electric vehicles; a focus in recent years. Saki develops X-ray inspection equipment suitable for SMT process board and component inspection, as well as power module inspection. Through unique Planar CT technology and calculation technology, Saki equipment performs complex inspections at exceptional speed.

The difference between 2D X-ray inspection and 3D X-ray inspection

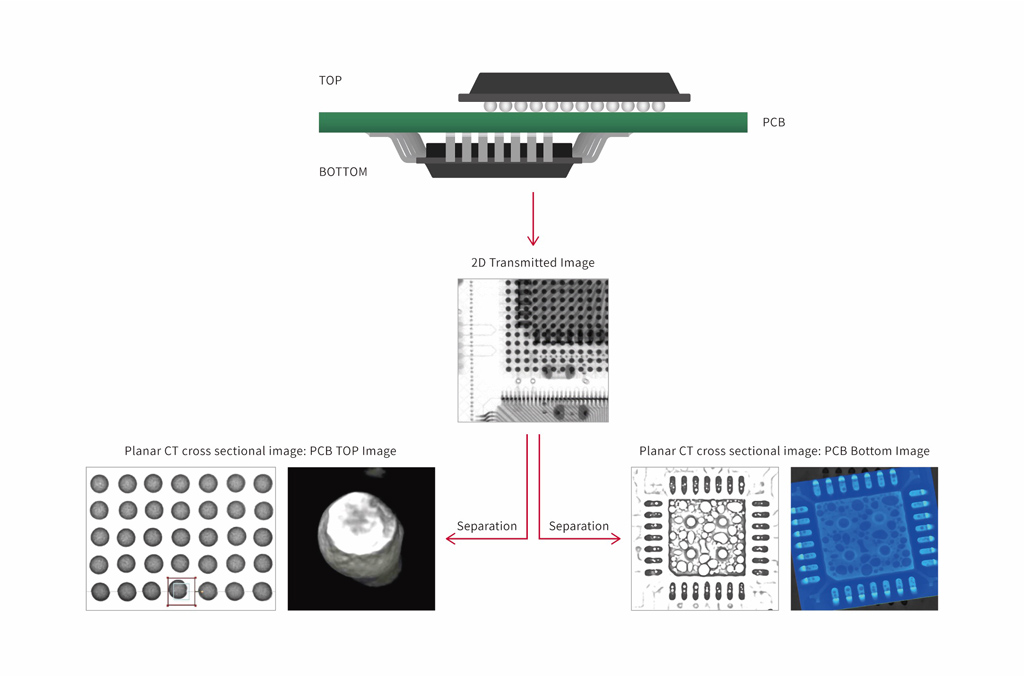

X-ray inspections typically utilize 2D (including 2.5D) images and tomographic techniques.

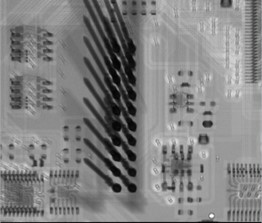

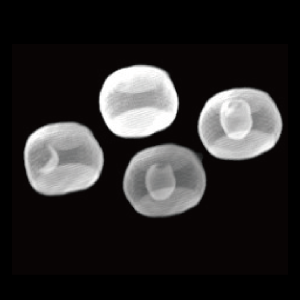

2D inspection allows for basic inspections, such as bridges and the presence or absence of solder. Although simple, two-dimensional images cannot be separated into top and bottom surfaces, making distortion and overlapping parts a regular problem, requiring operator skill to determine product quality.

Image acquired by 2D inspection machine

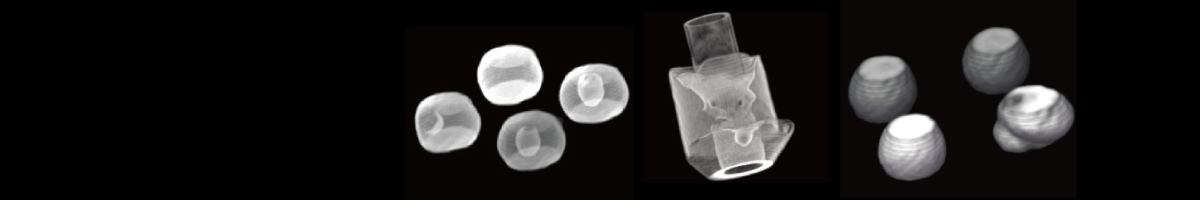

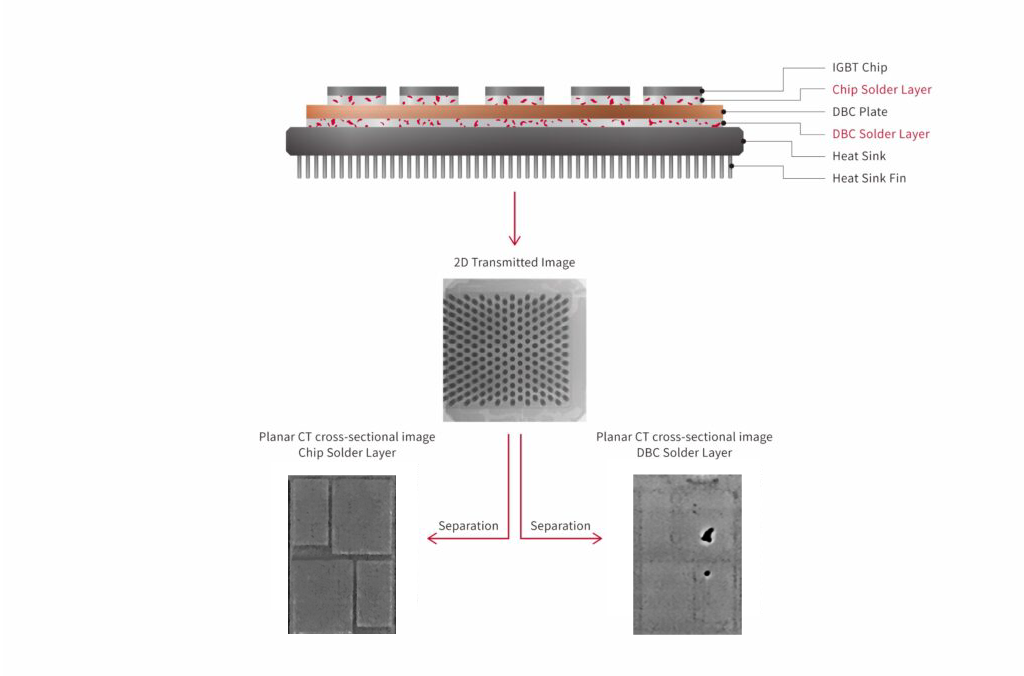

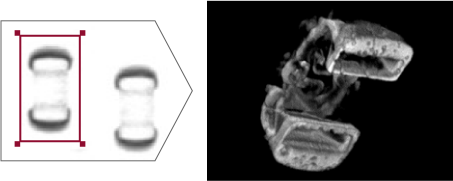

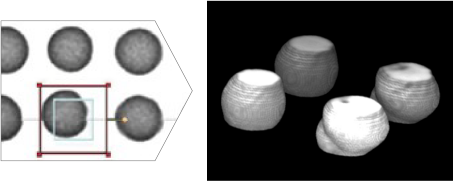

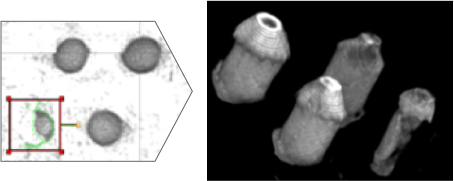

In contrast, 3D CT inspection and tomography results in high-definition images, able to expose previously hidden solder void inspections and non-wetting inspections. Saki’s 3D X-ray inspection system uses unique Planar CT technology to calculate hundreds of tomographic images of the space containing the board, generating true three-dimensional data for inspection and analysis. By capturing images with high separation between the top and bottom surfaces, interference from shadows or distortions caused by overlapping parts and minimized and precision inspection accuracy is achieved.

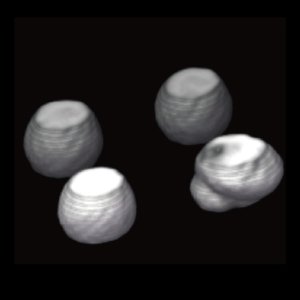

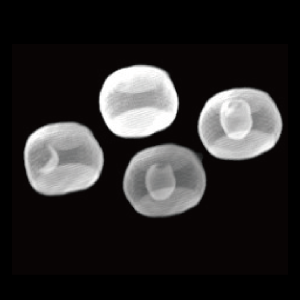

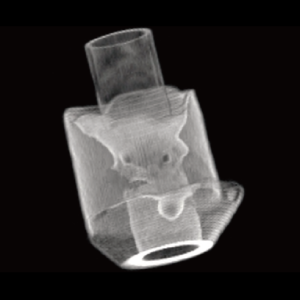

Images acquired by a true 3D inspection machine

Head-in-Pillow

Void Defect

PTH Solder Defect

01

Saki’s unique Planar CT technology

Imaging phase

Saki’s X-ray inspection equipment features an X-ray source with a small focal diameter installed in the upper center of the equipment. The sample stage and detector stage synchronize and move in a circular motion, capturing multiple images at different angles. Saki’s unique high-precision control enables images with clear edges to be obtained.

Unique Planar CT Technology

3D image generation phase

By compiling multiple images from different angles with the CT calculation, hundreds of tomographic images are instantly generated. Using the 3D imagery created by this process, high-definition inspections are undertaken that discover all defects including small voids.

02

Planar CT Technology Advantages

Saki’s Planar CT method performs accurate inspections on historically-difficult double-sided printed circuit boards by acquiring images with high separation. By eliminating the shadows of components mounted on the opposite side, solder inspection of power modules is undertaken with extremely high precision.

PCBs

IGBT power module

03

Image processing technology that increases defect detection ability

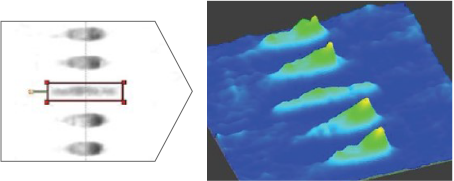

Some defects, such as board warpage and voids in difficult to predict locations, require advanced image processing technology to detect. Saki’s X-ray inspection equipment uses accurate board surface correction and true 3D inspection to accurately identify the inspection target and not miss minute defects.

Substrate warpage compensation technology

Additional technology is applied that automatically corrects the height of board warpage. Accurate height measurements are performed by automatically searching the board surface on which the inspection target is mounted and correcting the image. This technology is also applied in power module inspection to extract the solder surface to be inspected and correct board warpage.

Image process technology

Seamless 3D images are generated by correcting the joints of parts that span multiple FOVs in the X, Y and Z directions. Through this, 3D information on the entire board surface is acquired.

04

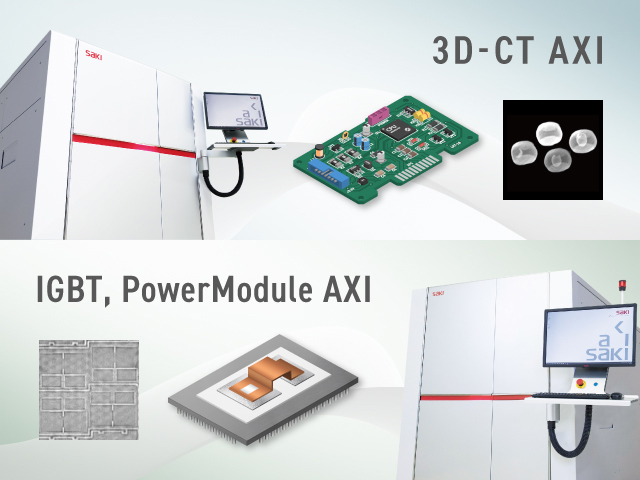

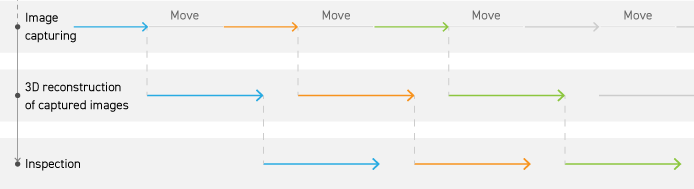

High-speed inspection that also supports inline processing

Compatibility with in-line systems is key to maintain speed in X-ray inspection. Saki’s X-ray inspection equipment achieves both high-precision inspection and unparalleled speed, with 3D-CT AXI for SMT processes operated in-line. The high-speed technology is also applied to X-ray inspection equipment for inspecting power modules.

05

Three features that achieve high speed

High precision hardware design

Wide area imaging detector

By significantly expanding the area that can be viewed in each image, imaging speed is improved by 50%.

Original calculation technology

The consistent image processing process from image capture has been optimized to decrease data processing time and reduce unnecessary waiting time.

Simultaneous processing

06

Pursuing ease of use and easy operation

3D X-ray inspection, which can perform highly complex inspections, is often perceived as difficult to operate. In particular, there may be concerns about the creation of inspection programs and the hours required for operation. Saki’s X-ray inspection equipment focuses on reducing operating overheads.

Common programming platform with AOI

Saki’s 3D-CT AXI reduces workload and operator time by utilizing AOI program creation data introduced in the same SMT process. The rigid hardware design and full board imaging technology enable program management to operate in identically to AOI.

Same operability as AOI

Saki’s 3D-CT AXI is equipped with the same software platform as AOI, so it can be easily operated with the same operability as AOI, dramatically reducing both operational man-hours and training. Integrating AOI and AXI inspection results within a single display achieves consistent quality control throughout the line.

07

Realization of inspections

Saki’s X-ray inspection equipment applies a spread of efficient algorithms and filter functions to handle a wide range of inspection targets. Two types of X-ray sources with different voltages enable high-precision inspection of power modules and IGBTs as well as SMT processes.

08

SMT process inspection

IC parts / chip parts solder defects

BGA solder void defect / non-wetting

Insufficient solder filling for inserted parts

09

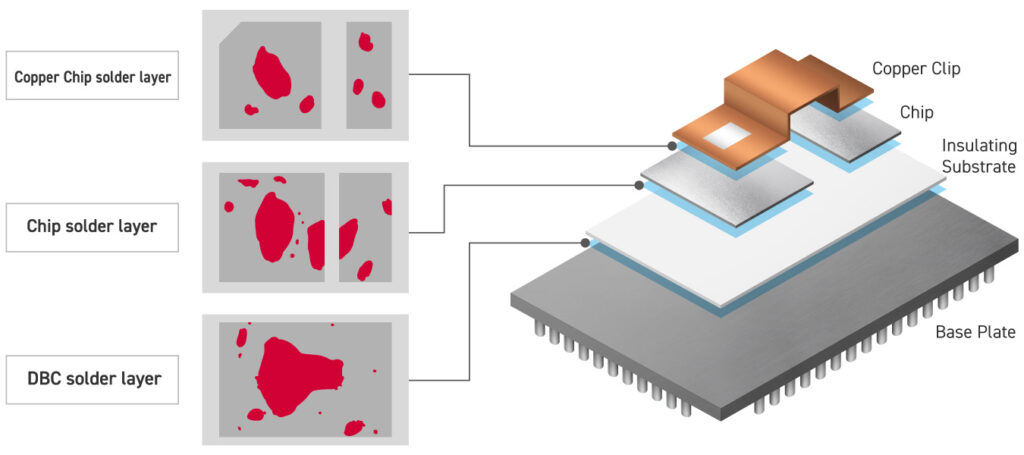

Power module / IGBT inspection

- Inspection in accordance with IPC standards

- Solder layer void inspection of power module products

Supports 3-layer solder inspection