3D Solder Paste Inspection

Machine

3D-SPI

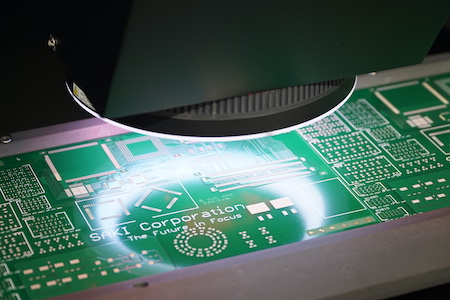

Saki’s high-speed, high-precision 3D-SPI machines specialize in the inspection of SMT process solder printing. 3D-SPI machines inspect and analyze a wide range of potential problem points, including the measurement of solder paste area, height, and volume; as well as bridge, solder horn, and BGA coplanarity compliance.

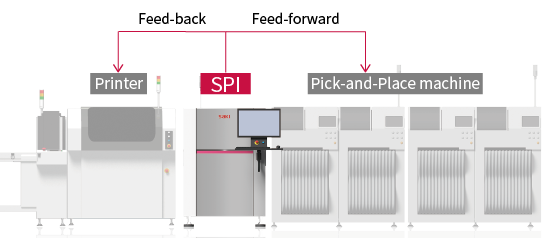

The quality of the entire production line is ensured through machine-2-machine co-ordination with solder printing and pick-and-place machines.

Hardware designed for high-speed and high-accuracy inspection

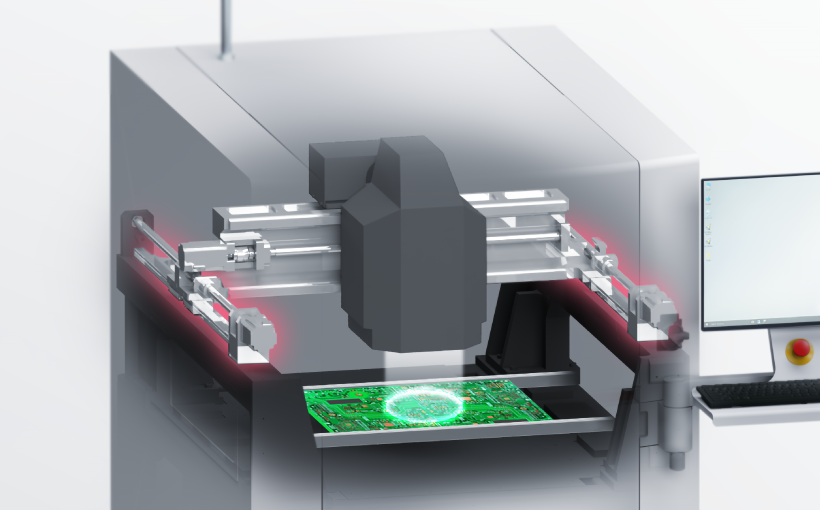

The design employs an ultra-rigid gantry and biaxial drive with an ultra-high-definition linear scale, enabling high-speed movement of the optical head with incredible stopping position accuracy.

Faster data processing thanks to Saki’s unique dedicated software

All imaging and processing software is developed by Saki in-house, improving hardware optimization and inspection algorithms – leading to faster, superior data processing.

Robust hardware structure that guarantees an extended lifetime of continued high-quality inspection

With its ultra-rigid gantry, biaxial drive, and ultra-high-definition linear scale, the 3D-SPI has high repeatability and contributes to maintaining the stability and quality of inspection result data. Stable inspection is guaranteed thanks to the strong, durable frame that provides reliability for 15 years and beyond.

Self-diagnostic system

The self-diagnostics monitor equipment status in real time. Hardware checks during startup and prior to inspection greatly reduce the risk of sudden failures, and combined with consumable monitoring, allows maintenance to be efficiently scheduled with minimal downtime.

Time-Based Maintenance

Condition-Based Maintenance

Solder print inspection algorithms

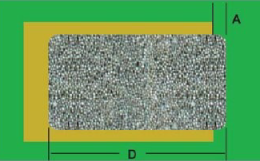

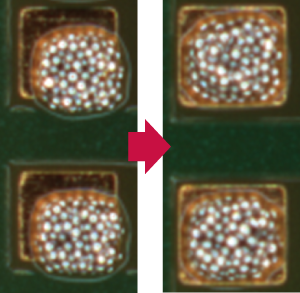

IPC-compliant inspection quality

Positional deviation of pad size is inspected based on the IPC-7527 quality standard for measurement allowances.

IPC-7527 Quality Standard Inspection

Printing Deviation Standard

Paste solder protruding from the pad Class 1,2,3: less than 25%

Actual Image

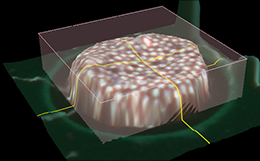

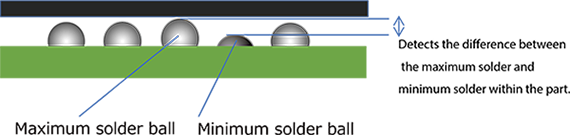

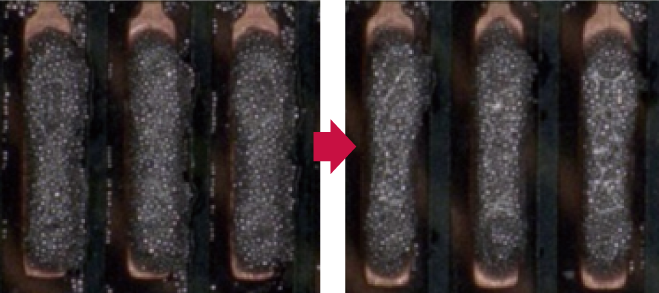

Coplanarity inspection

High I/O count device inspections benefit from improved coplanarity, with solder range analysis for height, volume and area that helps prevent post-reflow wetting.

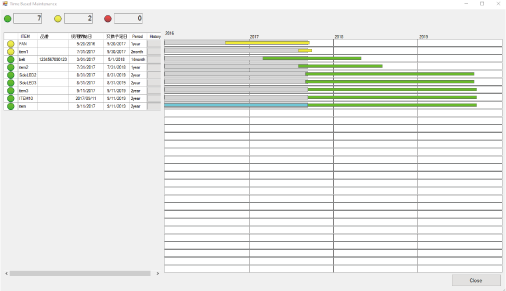

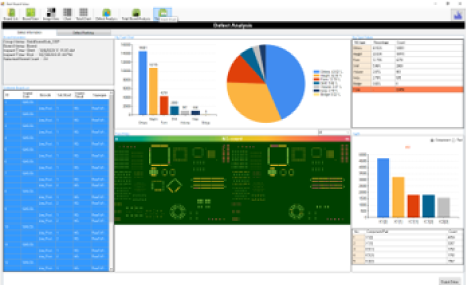

SPC functions for visualization of solder quality

Solder quality is managed and maintained through comprehensive monitoring of board solder amounts and defect trend analysis. Extensive reporting functions and data analysis tools allow for export of defect type rankings and yield charts.

Defect Analysis

Yield Chart

Feed-back from SPI to screen printer

The accuracy of solder printing is improved thanks to feeding back solder printing position misalignment data from the SPI to the solder printing machine. Additionally, metal mask cleaning instructions are automatically communicated to prevent solder printing defects.

Correction of the Print Position

Automatic Cleaning Instructions

Feed-forward from SPI to pick-and-place machine

Component mounting position is corrected by sharing information on solder printing position misalignment with the pick-and-place machine. Additional data on failed sub-boards is also communicated to avoid mounting components in these instances.

NG Board Skip

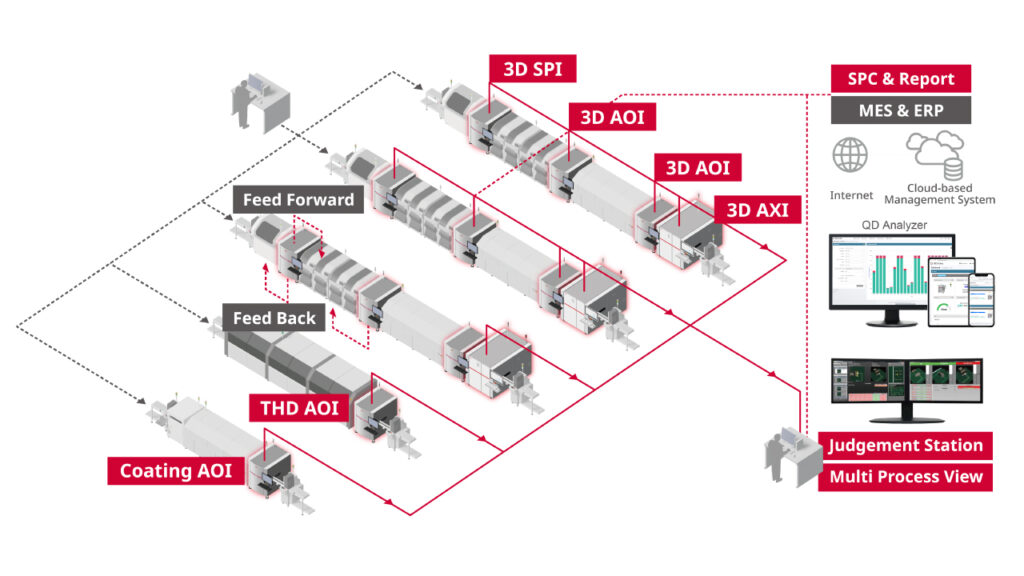

Saki’s Total Lineup Solution

Saki’s 3D-AOI uses a common platform with 3D-SPI and 3D-CT-AXI. The process is consistent throughout – from post-printing solder inspection using SPI, through to the inspection of mounted components.

Specification

| Dimensions | M | L | XL |

|---|---|---|---|

| Model | 3Si-MS2 | 3Si-LS2 | 3Si-ZS2 |

| Size (W)×(D)×(H)mm (in.) | 850 × 1430 × 1500 (33.46 x 56.30 x 59.06) | 1040 × 1440 × 1500 (40.94 x 56.69 x 59.06) | 1340 × 1440 × 1500 (52.75 x 56.69 x 59.06) |

| Resolution | 12μm、18μm | 18μm | |

| PCB Clearance | Top: 40mm(1.57 in.) Bottom: 60mm(2.36 in.) *1 | ||

| Electric Power Requirement | Single-phase ~ 200-240V +/-10%, 50/60Hz | ||

| PCB Size (W)×(L)mm (in.) | 50 x 60 – 330 x 330 (1.97 x 2.36 – 12.99 x 12.99)*2 | 50 x 60 – 500 x 510 (1.97 x 2.36 – 19.68 x 20.07)*3 | 50 x 60 – 686 x 870 (1.97 x 2.36 – 27.00 x 34.25) |

| Inspection Item | the measurement of solder paste area, height, and volume, bridge, solder horn, and BGA coplanarity compliance. | ||

| Dimensions | M |

|---|---|

| Model | 3Si-MS2 |

| Size (W)×(D)×(H)mm (in.) (in.) | 850×1430×1500 (33.46 x 56.30 x 59.06) |

| Resolution | 12μm、18μm |

| PCB Clearance | Top: 40mm(1.57 in.) Bottom: 60mm(2.36 in.) *1 |

| Electric Power Requirement | Single-phase ~ 200-240V +/-10%, 50/60Hz |

| PCB Size (W)×(L)mm | 50 x 60 – 330 x 330 (1.97 x 2.36 – 12.99 x 12.99)*2 |

| Inspection Item | the measurement of solder paste area, height, and volume, bridge, solder horn, and BGA coplanarity compliance. |

| Dimensions | L |

|---|---|

| Model | 3Si-LS2 |

| Size (W)×(D)×(H)mm (in.) (in.) | 1040×1440×1500 (40.94 x 56.69 x 59.06) |

| Resolution | 12μm、18μm |

| PCB Clearance | Top: 40mm(1.57 in.) Bottom: 60mm(2.36 in.) *1 |

| Electric Power Requirement | Single-phase ~ 200-240V +/-10%, 50/60Hz |

| PCB Size (W)×(L)mm | 50×60〜500×510 (1.97 x 2.36 – 19.68 x 20.07)*3 |

| Inspection Item | the measurement of solder paste area, height, and volume, bridge, solder horn, and BGA coplanarity compliance. |

| Dimensions | XL |

|---|---|

| Model | 3Si-ZS2 |

| Size (W)×(D)×(H)mm (in.) (in.) | 1340×1440×1500 (52.75 x 56.69 x 59.06) |

| Resolution | 18μm |

| PCB Clearance | Top: 40mm(1.57 in.) Bottom: 60mm(2.36 in.) *1 |

| Electric Power Requirement | Single-phase ~ 200-240V +/-10%, 50/60Hz |

| PCB Size (W)×(L)mm | 50×60〜686×870 (1.97 x 2.36 – 27.00 x 34.25) |

| Inspection Item | the measurement of solder paste area, height, and volume, bridge, solder horn, and BGA coplanarity compliance. |

*1 For dual mode, the PCB Clearance Bottom is 50mm (1.96 in.),

*2 For dual mode, the PCB Size is 50×60〜320×330 (1.97 x 2.36 – 12.60 x 12.99)

*3 For dual mode, the PCB Size is 50×60〜320×510 (1.97 x 2.36 – 12.60 x 20.07)

Use Case

TQ-Group

TQ-Group, a major German electronics solution provider, has installed Saki’s 3D-AOI and 3D-SPI to deliver even higher quality products.

Rohde & Schwarz

Rohde & Schwarz, a major German electronics solution provider, has installed Saki’s 3D-AOI and 3D-SPI to strengthen its manufacturing operations and deliver even higher quality products.

Smart Modular Technologies

Smart Modular Technologies, manufacturer of high-performance DRAM modules and solid-state disk drives (SSDs), has installed Saki’s 3D-AOI and 3D-SPI to handle miniaturization challenges and prepare for smart manufacturing.

Related Solutions

3D-AOI

3D Automated Optical Inspection Systems

3D-CT AXI

Inline 3D-CT Automated

X-ray Inspection Systems

3D-SPI