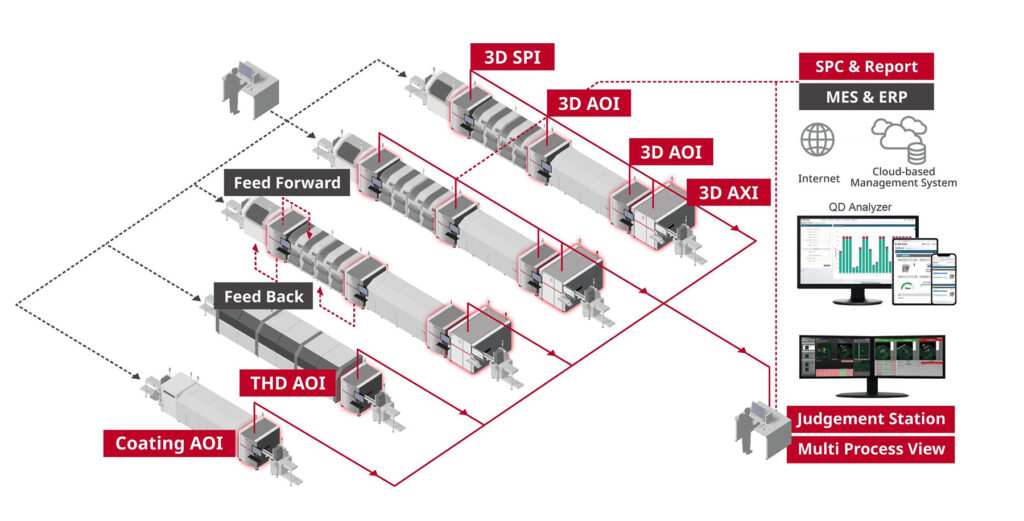

Total Solution

Saki produces a comprehensive line-up of inspection machines for SPI, AOI, and AXI, guaranteeing quality from the SMT to inserted parts processes. Manufacturing quality and production efficiency are supported by Saki’s realization of a true smart factory.

The manufacturing environment

Manufacturing sites deal with a variety of complex issues, including greater demands on quality, increasing product complexity, shorter delivery times, and labor shortages.

The diversification of inspection requirements leads directly to an increase in operational man-hours and costs.Additionally, it is becoming difficult to secure experienced personnel, with the skills to handle increasingly diverse testing.

The Value of Total Solutions

Saki’s total lineup solution is able to respond to all customer inspection requests, while contributing to reducing man-hours and costs, saving labor and improving the quality control of manufactured products.

01

Contributing to reduced costs and labor-saving

As the variety of inspection requirements increase, the number of inspection machines, operational time, and overall costs of quality assurance similarly rise.

The high-quality hardware design of Saki solutions reduce the risk of failure, lowering maintenance and replacement costs.

Additionally, with a unified platform for hardware and software, time spent in operation is reduced and associated costs diminished.

Further labor savings are accomplished as multiple inspection processes can now be handled by a single operator.

Key advantages of unified hardware

- Common maintenance parts between SPI and AOI → Reduction of costs to stock parts and manage maintenance

- Standardized calibration processes → Reduction of operational costs, jig calibration, and training time

Key advantages of the unified software platform

- Common operability for SPI/AOI/AXI → Reduction of training and programming overheads

- Common user interface for SPI/AOI/AXI → Reduction of operator training costs

- Unified program creation with SPI/AOI → Reduction of management time

02

Contributing to quality improvement and smart factories

Extremely precise inspection is required as inspection targets become increasingly complex, for example; high-density printed circuit boards and miniature components.

Furthermore, as the digitalization of factories, such as smart factories and IoT advances, the demand for digital production status and ongoing analysis based on data output from inspection machines increases.

Saki not only improves the quality of individual inspection machines, but also provides solutions that contribute to improving the quality of entire lines and factories.

M2M

Improving the quality of the entire line

QD Analyzer

Improving quality throughout the factory