Technology

Founded in 1994, Saki innovated in a crowded and competitive inspection machine market with unique high-speed inspection technology.

Since then, it has continued to grow alongside its customers by sensing new market needs and developing new products.

Introducing the latest technology that supports Saki’s advanced inspections.

SAKI Technology

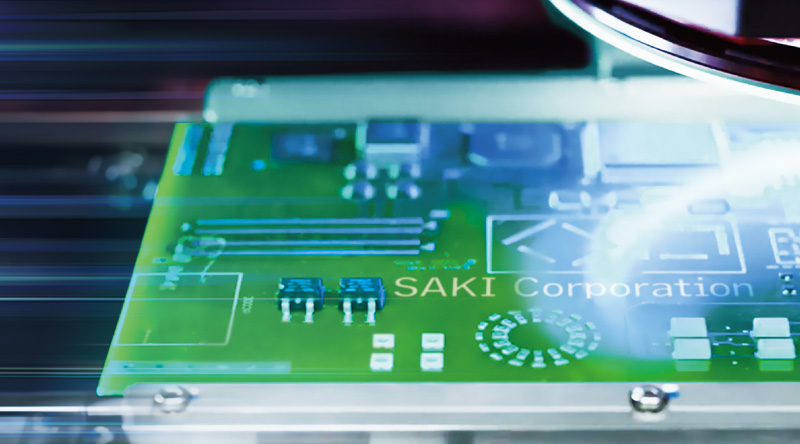

High-speed Inspection Technology

Wide-area imaging to shorten cycle time

Hardware structure that enables high-speed movement of the optical head

Advanced image processing to reduce unnecessary waiting time

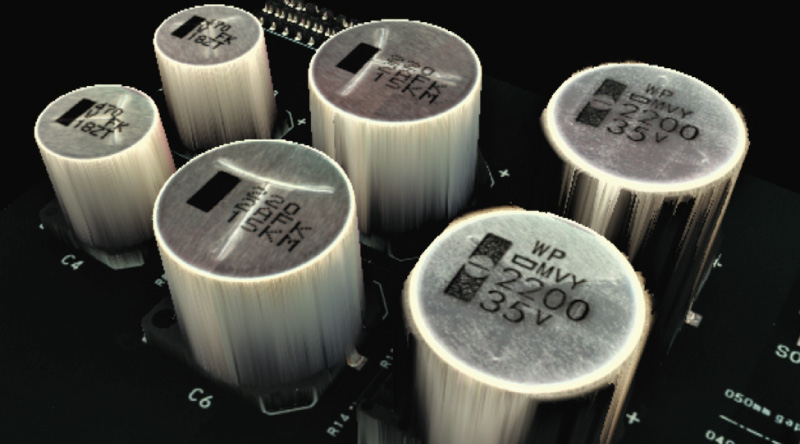

3D Image Acquisition Technology

Substrate surface correction technology

Image generation technology

Reduction of library management time

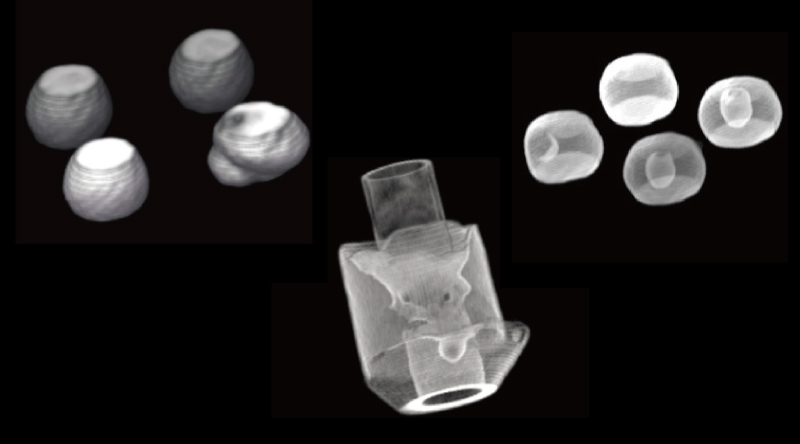

X-ray Inspection Technology

Saki’s unique Planar CT technology

Image processing technology that increases defect detection ability

High-speed inspection that also supports inline processing

SAKI Solution

AI Inspection Solution

AI Assist : Uses AI to re-assess, reducing operator workload

AI Inspection(AI OCR)

Saki’s Design philosophy – Upgrade to Excellence –

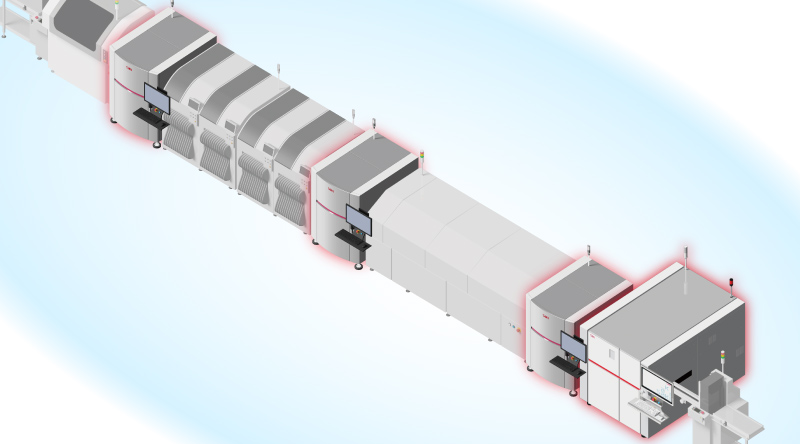

Modular Structure Customizable to Fit Inspection Needs

Expandable Items Selectable Specific to Inspection Needs

Total Solution

Contributing to reduced costs and labor-saving

Contributing to quality improvement and smart factories