SOFTWARE OPTION

Programming

Offline Programming and Debugging

The Editor system enables program generation and editing of inspection data and tolerances on an off-line computer while the inspection machine is in production. Quickly and efficiently create inspection programs and improve library detection capabilities without stopping operation.

01

Automatic inspection program creation function

The automatic program creation significantly reduces time spent creating inspection programs, especially essential for low-volume, high-mix production where a large number of programs are needed. Saki’s software utilizes a rich inspection library and automatic search technology to link component data and significantly reduce image creation time. Collaboration with third-party pick-and-place machine manufactures further improves work efficiency.

02

Easy Programming

・Cut programming time and effort with automated inspection program development tools

・Eliminate programming errors with comprehensive automated inspection data creation

03

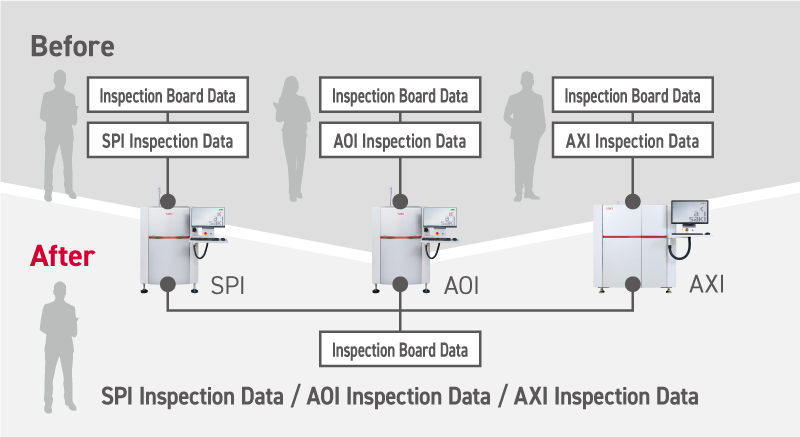

One Programming

Standardized inspection program data for SPI, pre-AOI, post-AOI, and AXI eliminates duplicate tasks and reduces line setup time to approximately one-third.

04

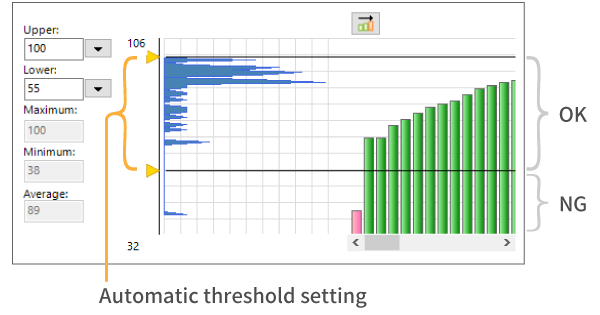

Automatic threshold-setting and offline debugging

The following functions significantly and rapidly improve the efficiency of detection:

Automatic threshold setting

This function automatically sets statistical thresholds that consider variations in previously-qualified parts obtained from mass production data. Usage allows the standardization of threshold adjustments, making swift and efficient updates to the inspection library.

Offline debugging

The offline collation of images of defective and excessive judgments allows the operator to adjust inspection parameters and update the inspection library in real time to reflect current results. This makes it possible to efficiently improve the detection power of the inspection library without halting operation.