SOFTWARE OPTION

SPC

SPC/Process Quality and Traceability Tool QD Analyzer

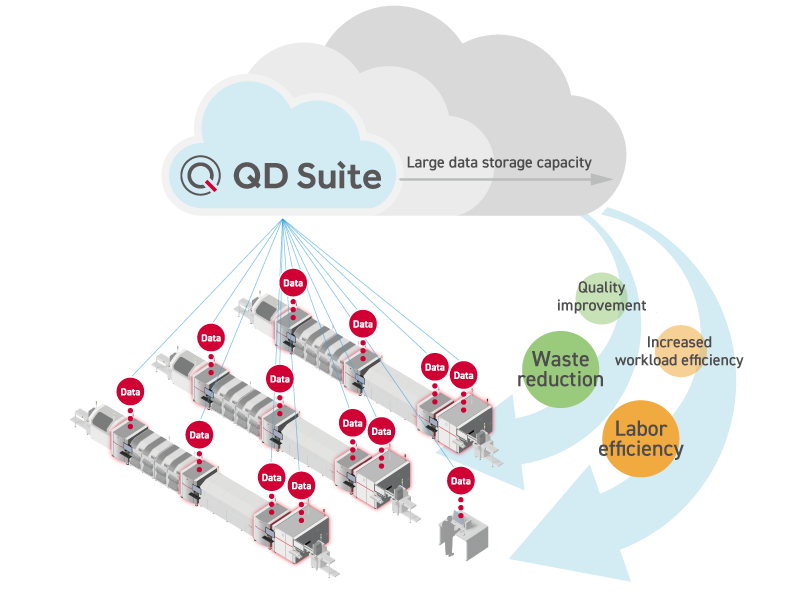

A cutting-edge database infrastructure allows long-term and large data & image storage while delivering exceptional data processing and retrieval process speed and efficiency.

With its advantages, the system plays a key role in realizing a smart factory.

Check factory productivity through large-capacity data collection and analysis

Data Collection : A single database capable of connecting up to 100 devices

↓

Data Analysis : Identify issues and root causes from data analysis to make targeted adjustments to boost performance and productivity.

↓

Productivity improvements : Waste reduction and workload optimization increase overall productivity, maximize efficiency and streamline operations.

01

Four Key Functions Powered by High-Capacity Database

Real-Time

- Real-time monitoring of overall production line performance.

- Acquire and display real-time insights about system operational status and lot production progress.

Customize Report

Customizable reporting functionality, tailored to specific needs such as quality assurance, inspection personnel, and equipment management.

Traceability

- Long-term storage of inspection results and history with detailed PCB images.

- Offers an inspection system formatcompatible database for easy use and fast search.

Analytics

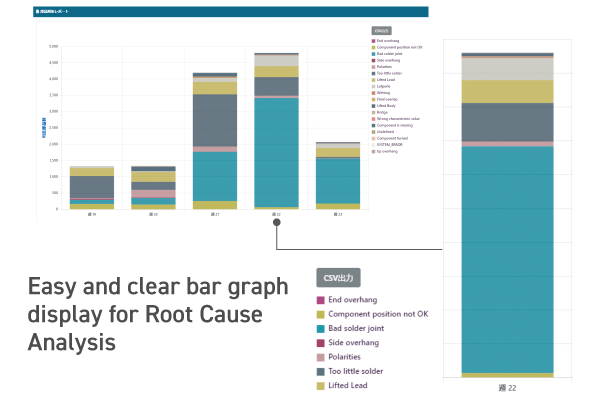

- Statistical Data Display

- Perform trend analysis of OEE-metrics and inspection results.

- Using component inspection results, analyse NG and false call causes and patterns.

02

QD Analyzer Benefits

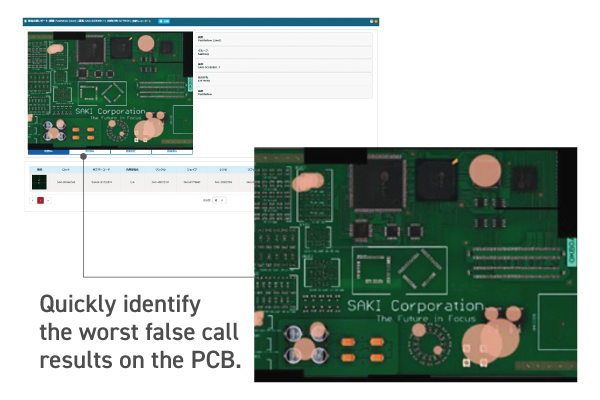

False Call Reduction

A customizable daily false call report is saved and used to identify components with greater false call ratios. The quick and intuitive report uncovers further root causes by analyzing saved images.

Production environment improvement to reduce defects

Use the worst ranking report and stored photos to identify defects and root causes. After finding the reason, countermeasures can be taken:

Increase in component shift occurances: maintain pick &place machine.

Increase in foreign objects: clean equipment and floors.

Component analysis report display

Production Efficiency Improvement

OEE monitors performance. It helps determine causes of lower performaning equipment.

The performance is presented in a useful and clear ‘at-a-glance’ report which offers detailed information for in-depth examination.