SOFTWARE OPTION

M2M

M2M co-ordination

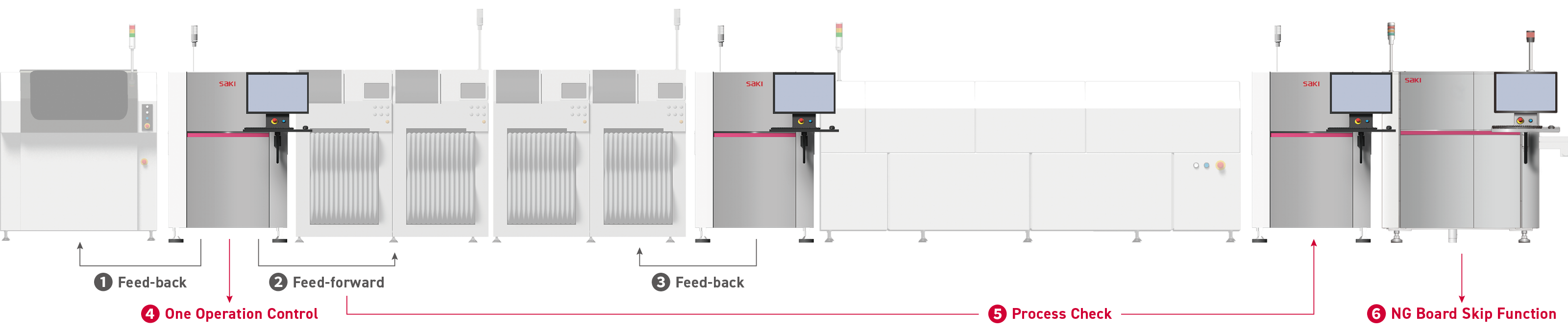

By linking inspection machines with solder printing and pick-and-palce machines, the quality control for the entire SMT line is improved.

Inter-device Coordination With Other Companies

① Feed-back (SPI▸Screen Printer)

② Feed-forward

③ Feed-back (AOI▸Pick-and-Place Machine)

Saki Link – Seamless Coordination Between Saki Devices

④ One Operation Control

⑤ Process Check

⑥ NG Board Skip Function

01

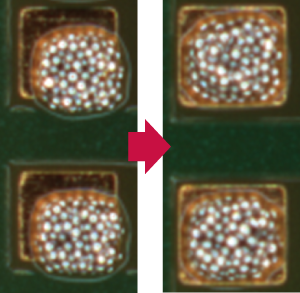

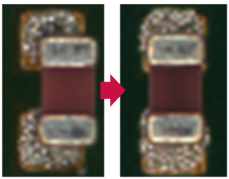

Feed-back from SPI to Screen Printer

Accuracy of solder printing is improved thanks to feedback of solder printing position misalignment from SPI to solder printing machine.

Additionally, metal mask cleaning instructions are automatically communicated to prevent solder printing defects.

Correction of the print position

Automatic cleaning instructions

02

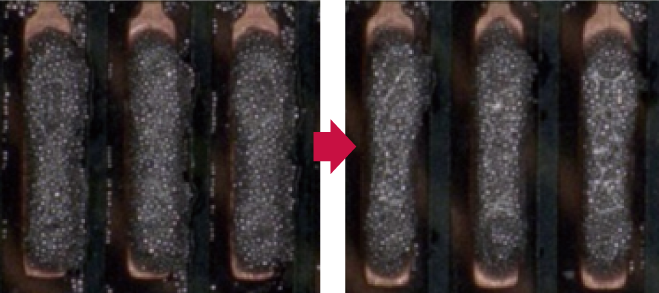

Feed-forward from SPI to Pick-and-Place machine

Component mounting position is corrected by the sharing of information on solder printing position misalignment with the pick-and-place machine. Additional data on failed sub boards is also communicated to avoid mounting components in these instances.

NG board skip

03

Feed-back from AOI to Pick-and-Place machine

SAKI’s AOI is capable of M2M collaboration with all major mounting machine manufacturers.

Feedback of the mounting position from AOI to the mounting machine strengthens product quality assurance.

Placement position correction

04

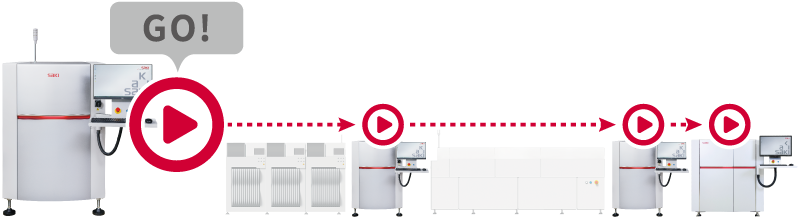

One Operation Control

Load a single inspection program to start/stop all connected devices automatically.

05

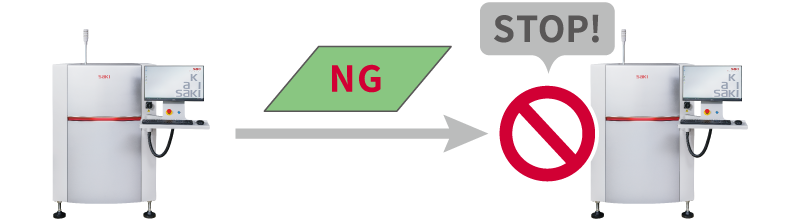

Process Check

Prevent defective boards from moving to post-processing, if an upstream inspection machine flags a board as NG, it is marked as an “Operation Error”.

06

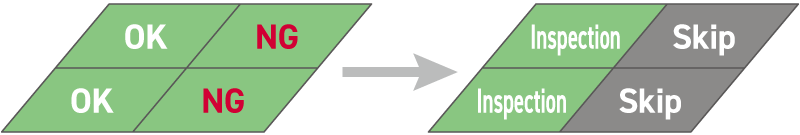

NG Board Skip Function

Reduces X-ray inspection time by sharing AOI inspection results with the X-ray system, enabling bad-marked boards to be skipped.