TECHNOLOGY

SAKI’s Design philosophy – Upgrade to Excellence –

Upgrade to EXcellence

SAKI’s SPI/AOI provides new value with Upgradeable Hardware Design

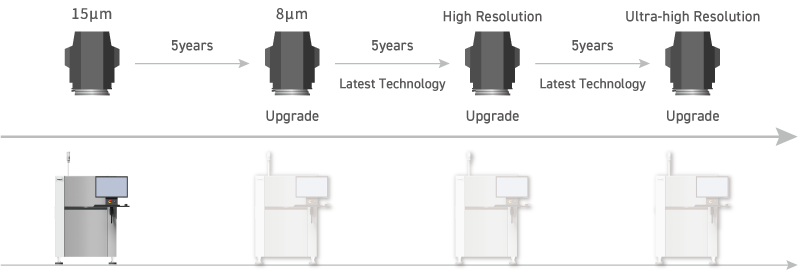

What is SAKI’s SPI/AOI Upgradeable Hardware Design?

SAKI’s distinctive concept allows optical head module replacement even after decades of use, enabling adaptability to changing inspection needs.

SAKI’s durable hardware combined with a modular structure is designed for long-term use.

01

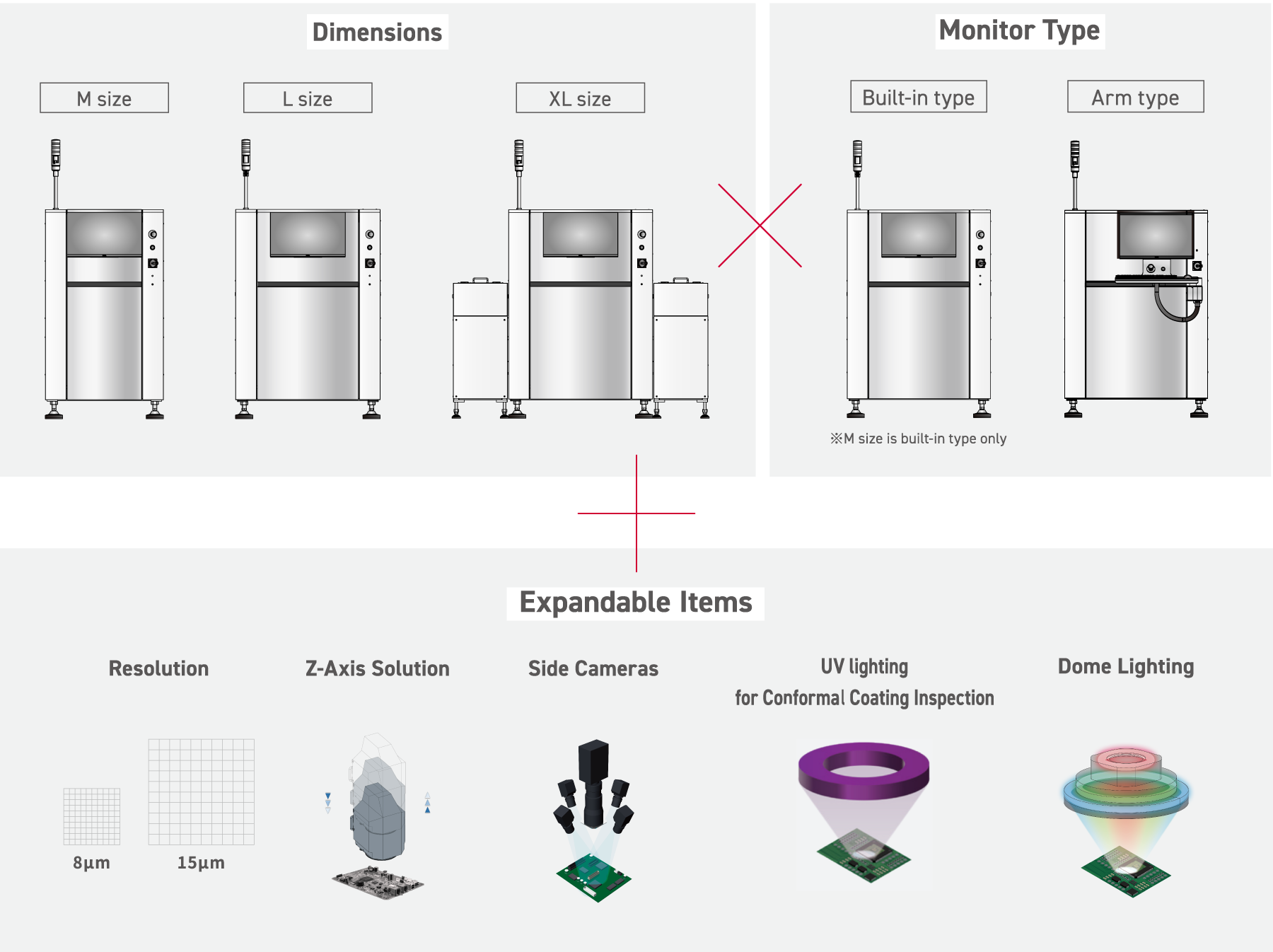

Modular Structure Customizable to Fit Inspection Needs

Dimensions

Selectable sizes according to inspection requirements; M, L, XL.

M size supports space-saving operation and XL size supports inspection of large boards.

Monitor Type

Built-in monitors enhance productive area.

02

Expandable Items Selectable Specific to Inspection Needs

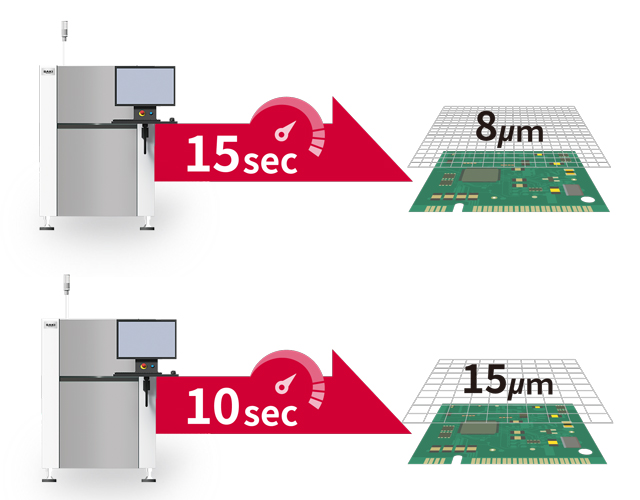

Resolution

SAKI has handled the challenge by designing the optical heads for fast and easy replacement onsite, allowing users to quickly switch between 8-micron (µm) and 15-micron (µm) resolution when setting up the system. As a rule, high-density mounted components are inspected at 8µm resolution, while 15µm ensures a larger camera field of view if high-speed inspection is the priority. To ensure productivity is not lost, the optical head must be designed for rapid changeovers

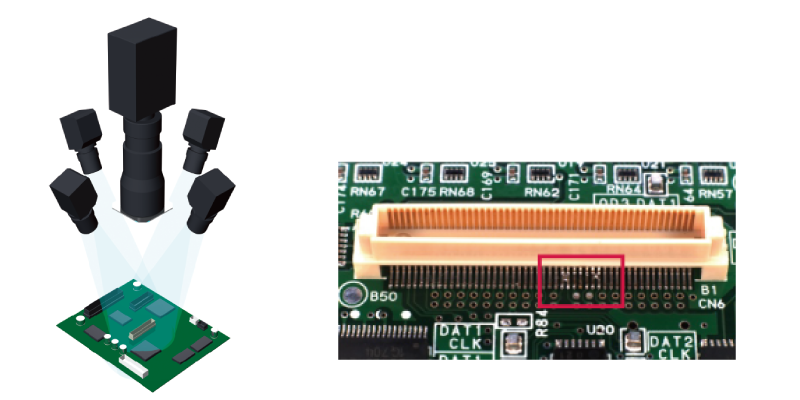

Side Cameras

Quad side camera system ensures inspection of dead angles and areas missed by overhead camera.

It enhances inspection capability for quad flat no-lead (QFN) IC packages, as well as detecting soldering and bridging defects associated with connectors.

Z-Axis Solution

Supports various surface mount inspection processes such as press-fit, THT, and jig deployment.

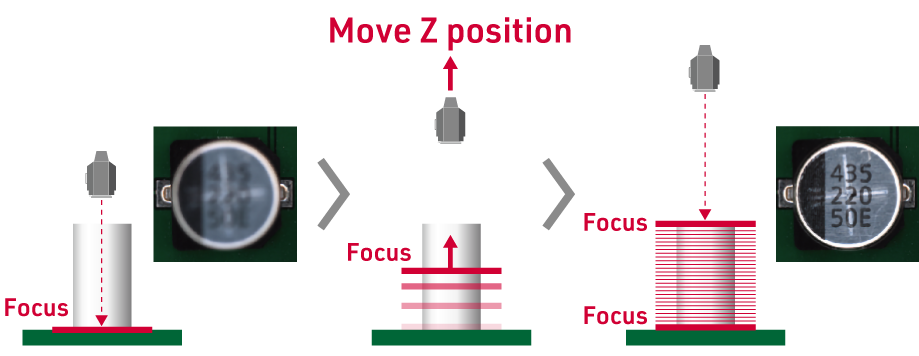

・Tall component Polarity Inspection and OCR

The focus range is adjusted for both the PCB surface and the top of tall components, improving inspection accuracy of characters (OCR,OCV) and polarity inspection.

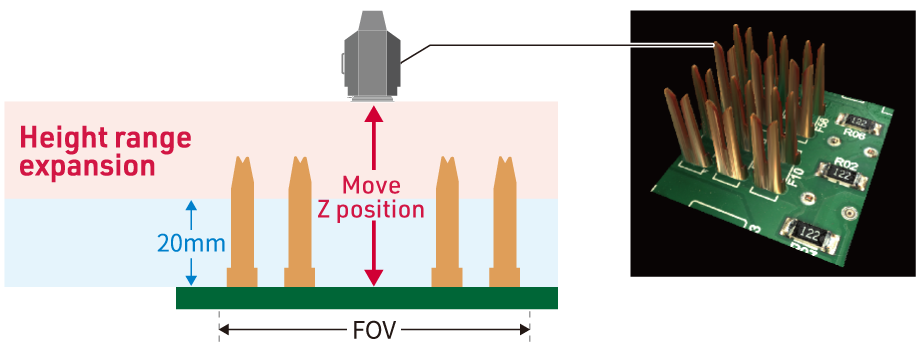

・Height Measurement Range Extension

The height measurement range extends up to 40mm. SAKI’s unique technology captures and reconstructs multiple images for simultaneous solder surface and tall component height measurement. High-precision measurement of press-fit pins is also possible.

Furthermore, the system can inspect carrier fixtures of varying substrate surface heights and 3D-AOI with Z-axis can handle diverse inspections far beyond SMT.

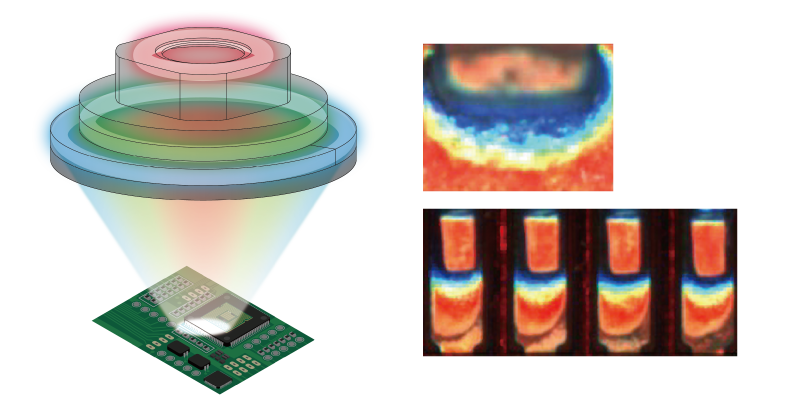

Dome Lighting

Dome lighting enhances color contrast in non-flat areas, ideal for automotive and other high-quality, high-reliability applications and enables solder fillet inspection in compliance with IPC inspection standards.

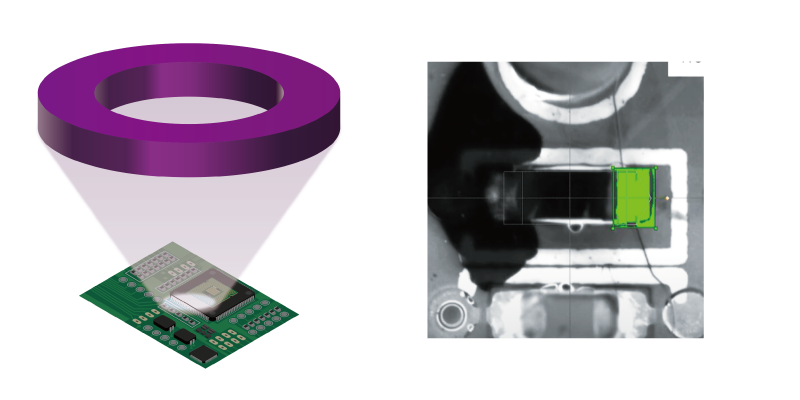

UV lighting for Conformal Coating Inspection

UV Lighting ensures conformal coating inspection. Extra Component Detection (ECD) is also possible.

Upgrade to EXcellence

By adapting to industry trends and aligning with customer needs, SAKI ensures ongoing innovation, focusing on enhancing inspection capabilities through optical unit upgrades. In addition to giving futureproof assurance and results in low total cost of ownership, it also generates many added values such as solving environmental problems and responding to new inspection trends.

Related Solutions

3D-SPI

3D Solder Paste

Inspection Machine

3D-AOI

3D Automated Optical

Inspections